Introduction

Compressed air is often the most expensive utility in a production plant — yet one of the least optimized. At this facility, the challenge was magnified by having two separate compressor rooms, 150 meters apart, each operating independently. In total, the site ran seven compressors from different manufacturers (5 Atlas Copco, 2 Sullair), supported by seven dryers.

Without a unified control system, the plant faced constant performance issues:

- Unstable pressure levels, causing operational inefficiencies

- Frequent load/unload cycles and compressor starts

- Uneven distribution of running hours across compressors

- Increased energy costs due to poor sequencing and wasted power

The management team partnered with CALMS to solve these issues without investing in new hardware.

Project Objectives

The goals of this project were clear:

- Stabilize system pressure across both compressor rooms.

- Integrate monitoring for compressors and dryers into one transparent system.

- Optimize sequencing to minimize wasted energy.

- Balance operating hours to extend compressor lifespan.

- Implement predictive maintenance tools to reduce unplanned downtime.

The CALMS Solution

Advanced Monitoring

To gain full visibility into system performance, CALMS deployed a comprehensive monitoring infrastructure:

Dew Point Sensors: Three sensors installed to continuously measure air dryness.

Wet & Dry Pressure Monitoring: Enabled tracking of pressure drops across dryers and filters, ensuring system losses were visible.

Dryer Integration: Each of the seven dryers was equipped with a current transformer on one phase to calculate its individual power consumption, added to total system power. Dryer fault signals were also connected, giving operators real-time alerts.

Compressor Connectivity: All seven compressors were connected via Modbus, despite being from different brands. Key parameters monitored included:

- Discharge pressure & temperature

- Air filter differential pressure

- Oil separator pressure drop & temperature

- Cooling water outlet temperature

- Operating and loaded hours

- Number of starts

This vendor-independent data capture is a cornerstone of CALMS: unbiased, holistic monitoring across mixed-brand fleets.

Control & Optimization

At the heart of the system, CALMS installed a CAL-PM-8 controller with a CAL-OPT extension, connected via fiber optic link between the two rooms.

The control strategy included:

- Average Pressure Regulation: Both rooms were regulated based on the average value of dry air pressure, ensuring consistent system-wide stability.

- Equal Running Hours Mode: Load distribution logic balanced compressor operating hours, extending lifespan and reducing maintenance.

- VSD Load Sharing: The two VSD compressors, located in different rooms, were controlled to run at nearly identical load percentages. This dramatically reduced the frequency of load/unload cycles on fixed-speed compressors, while keeping pressure tight around the setpoint.

Results

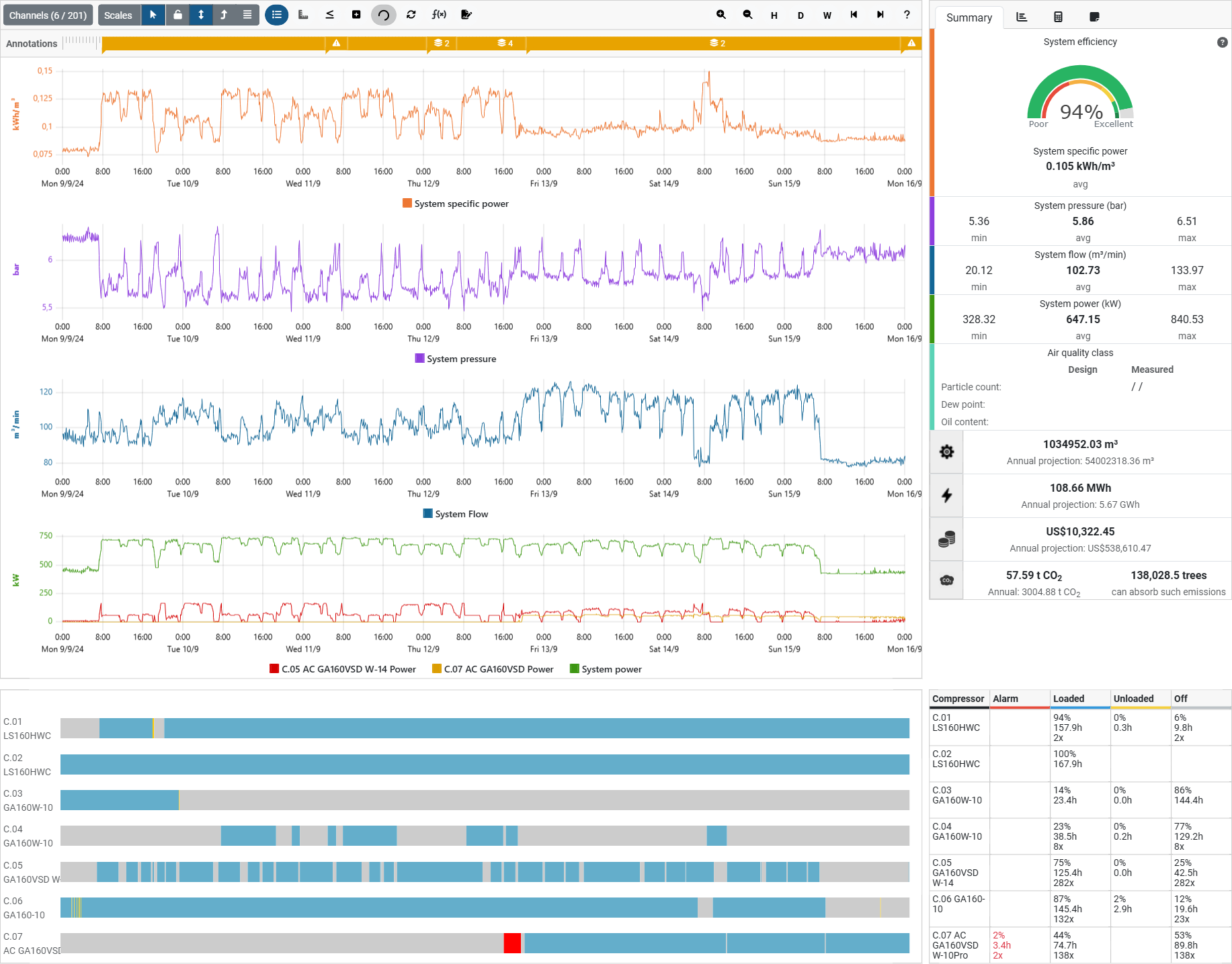

Before CALMS:

Large pressure swings

Frequent load/unload cycles and compressor starts

Uneven wear between machines

High specific power consumption

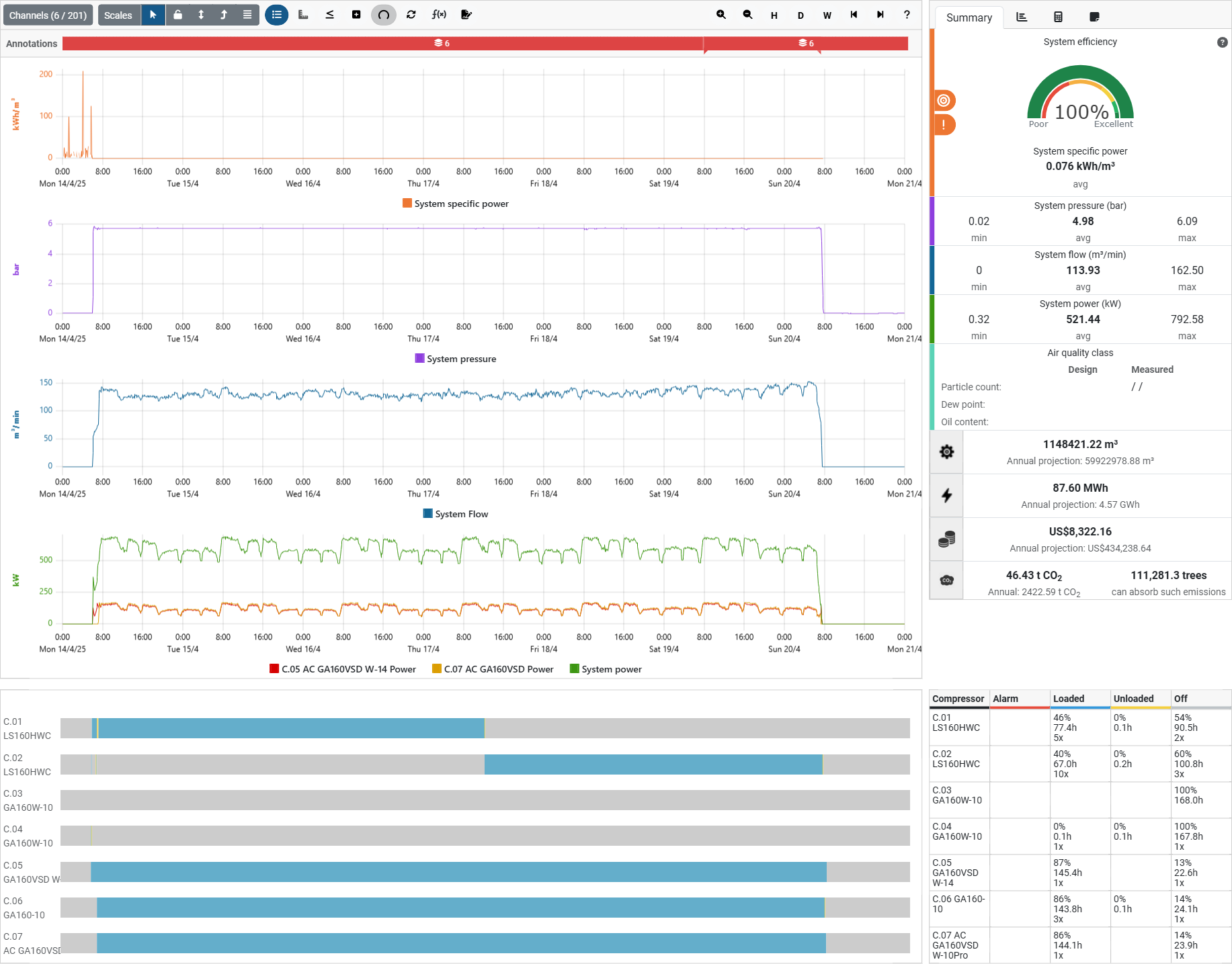

After CALMS:

Stable pressure: Variation reduced to within 0.1 bar of setpoint

Optimized load sharing: Balanced operation across both VSDs

Fewer starts/stops: Reduced stress on fixed-speed compressors

Lower energy waste: Specific power significantly improved

System transparency: Full data visibility for predictive maintenance and benchmarking

Key Learnings

- Fiber optic connectivity enabled true multi-room integration — proving distance isn’t a barrier with CALMS.

- Vendor independence (Atlas Copco + Sullair) showed that mixed fleets can be optimized as one system.

- Granular monitoring (dew points, dryer power, filter differential pressure) revealed hidden inefficiencies often missed in traditional setups.

- Smart load sharing is a game-changer: not only does it save energy, it reduces mechanical stress and downtime.

Conclusion

This case study demonstrates how CALMS can transform even complex, multi-room compressed air systems into stable, efficient, and transparent operations — all without replacing existing hardware.

By combining advanced monitoring, fiber-linked control, and AI-driven optimization, CALMS delivered measurable improvements in reliability, energy efficiency, and sustainability.

📩 Interested in what CALMS can do for your facility?

Contact us for a free consultation

Dolenjska cesta 83, 1000 Ljubljana, Slovenia

Dolenjska cesta 83, 1000 Ljubljana, Slovenia