Introduction

Sandoz Slovenia, a prominent pharmaceutical company specializing in the production of antibiotics, grappled with challenges concerning its compressed air system. Equipped with CALMS permanent monitoring for almost two years, the company sought to improve its 13 bar and 7 bar compressed air systems.

Executive Summary

The compressed air system at Sandoz Slovenia faced two primary issues:

- The 13 bar compressor experienced on-off cycling with unstable pressures, resulting in inefficiencies.

- The 7 bar system, with increased air demand, left no spare air, leading to operational hiccups.

By utilizing the insights from the CALMS management system and its monitoring capabilities, the two compressed air systems were successfully connected, yielding enhanced efficiencies and stable operations.

The Challenges

As the service provider responsible for the compressed air system, our aim was to maintain best-in-class efficiency, online support, and monthly energy reports. However, the peculiar on-off consumption in the 13-bar system persisted even after replacing the on/off compressor with a new variable speed screw compressor. Meanwhile, the increased consumption in the 7 bar system posed its own set of challenges.

The CALMS CFC Solution

Our permanent compressed air management system facilitated online efficiency monitoring and allowed for real-time adjustments in system settings based on demand variations. This ability to monitor, compare, and adjust quickly emerged as a key solution component.

The Results

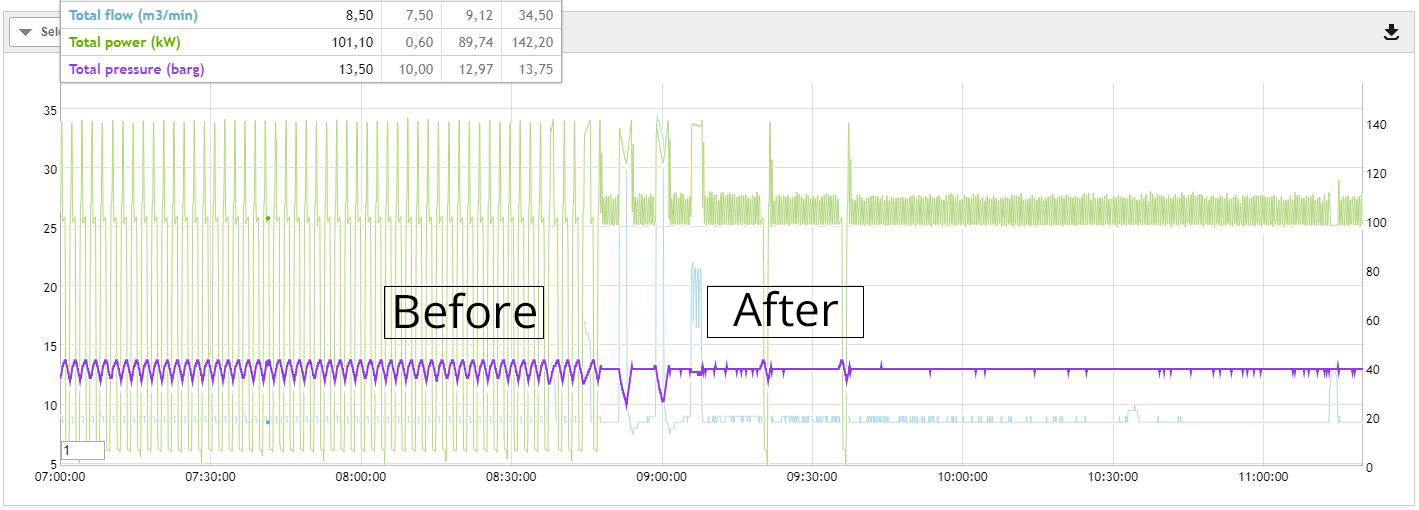

- 13 Bar System: Operations saw improvements with the compressor now running at an average load of 80%. There was a marked reduction in unloading/stopping of the compressor, resulting in enhanced reliability and fewer breakdowns. The pressure remained stable, fluctuating by only +-1%.

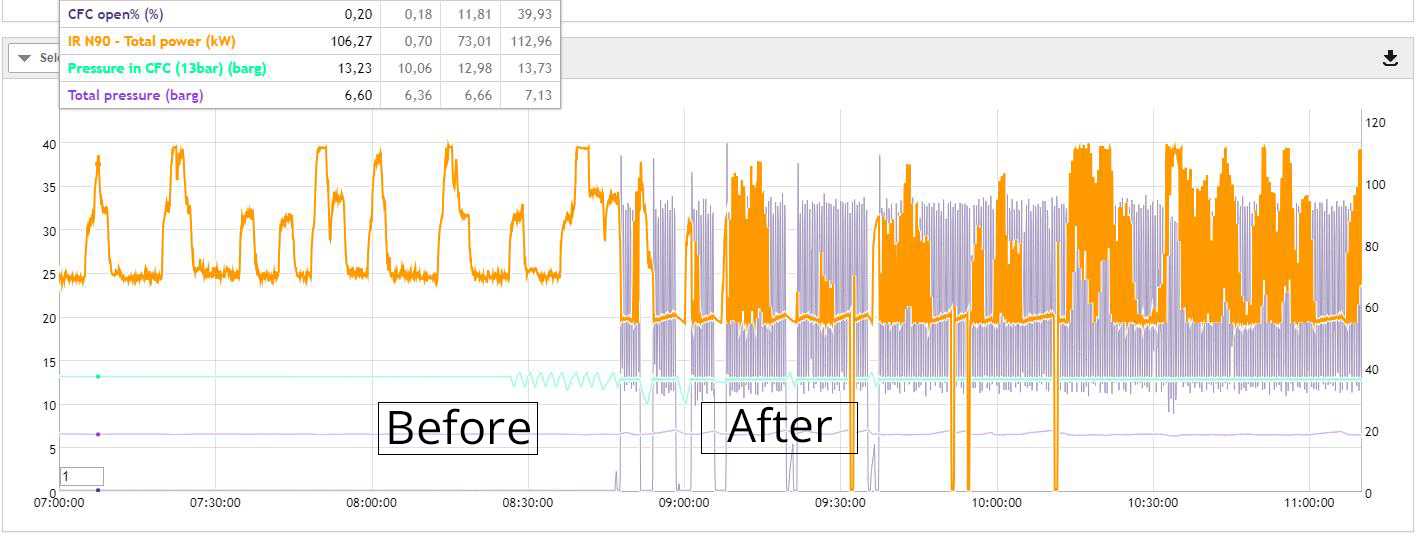

- 7 Bar System: Similarly, this system achieved stable operations with the compressor running at an 80% load and consistent pressure stability within +-1%. The necessity to purchase a new compressor was eliminated, offering cost savings.

- Continuous Oversight: The continuous monitoring capability provided by the CALMS management system ensures that the compressed air system remains optimized, flagging potential issues before they become critical.

Conclusion

The collaborative efforts between Sandoz Slovenia and our CALMS management system resulted in both efficiency gains and cost savings. Through continuous monitoring and swift adjustments, the pharmaceutical company can now rely on a robust and optimized compressed air system, crucial for its antibiotics production.

For more insights and details about our solutions, please visit CALMS official website.

Dolenjska cesta 83, 1000 Ljubljana, Slovenia

Dolenjska cesta 83, 1000 Ljubljana, Slovenia